Reviewing the Advantages of Aftermarket Parts in the Upkeep of Machinery and Heavy Devices

In the world of machinery and heavy tools maintenance, the conversation bordering the use of aftermarket components is one that sparks inquisitiveness and triggers a more detailed examination. As specialists entrusted with making sure optimum efficiency and longevity of equipment, it ends up being vital to explore the advantages that aftermarket parts use.

Cost-Effectiveness of Aftermarket Parts

Using aftermarket components for equipment maintenance has been revealed to dramatically enhance cost-effectiveness without endangering high quality or efficiency. These parts, which are produced by third-party manufacturers as options to original devices manufacturer (OEM) parts, provide various benefits in terms of price and accessibility. Aftermarket components are normally valued lower than their OEM counterparts, making them an extra budget-friendly alternative for services wanting to minimize maintenance expenses without compromising reliability.

One essential element adding to the cost-effectiveness of aftermarket components is the open market they exist in. With multiple producers creating these components, prices ends up being much more competitive, ultimately benefiting the consumer. The schedule of aftermarket parts is generally greater compared to OEM components, as they can be sourced from a range of representatives and vendors. This accessibility not only decreases preparations for repair services yet likewise offers versatility in selecting the best-priced choice without endangering on quality.

Wide Schedule and Access

Aftermarket parts, recognized for their cost-effectiveness in machinery upkeep, demonstrate noteworthy benefits through their wide accessibility and availability in the market. Unlike OEM (Original Tools Manufacturer) components that might be limited to certain car dealerships or makers, aftermarket components are commonly created by various third-party makers (Bobcat Aftermarket Parts). This widespread manufacturing results in a broad circulation network, making aftermarket components conveniently available to consumers across various places

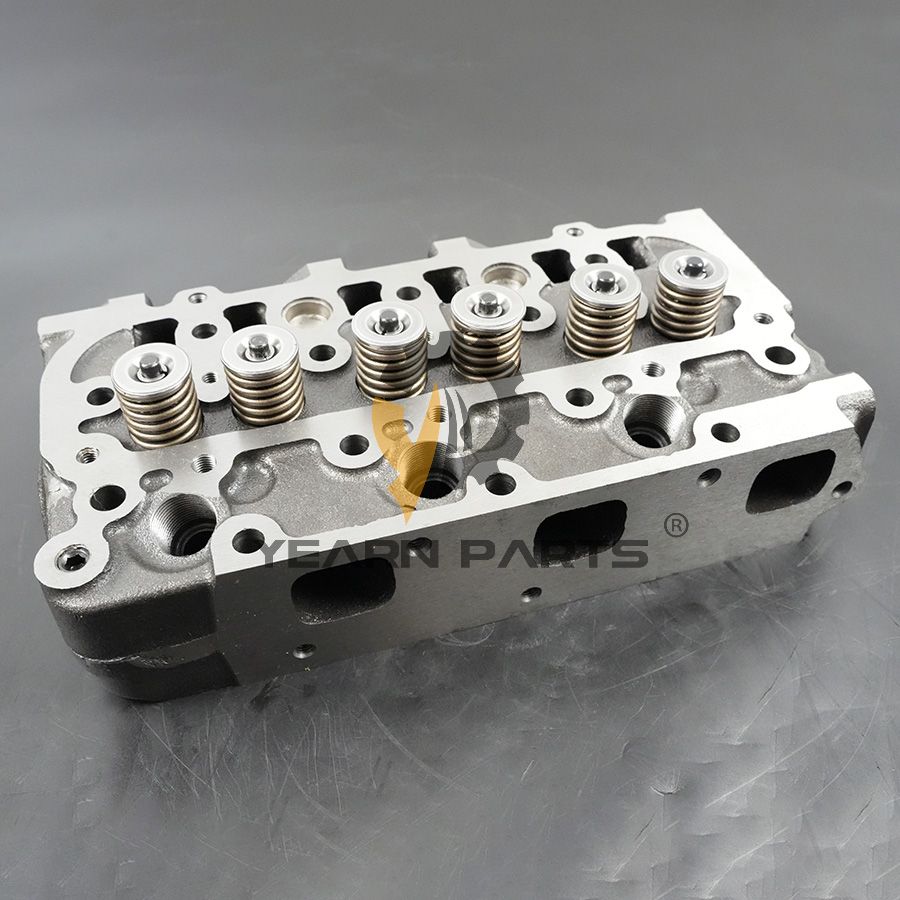

Similar Quality to OEM Components

With innovations in making procedures and top quality control standards, aftermarket components currently use a level of high quality that is comparable to OEM components. In the past, there was a typical misconception that aftermarket components were of inferior quality compared to initial equipment maker (OEM) parts. Due to technological development and raised competitors in the aftermarket market, several aftermarket makers have significantly improved their production procedures and products to fulfill or even go beyond the quality standards set by OEMs.

Among the major reasons aftermarket parts currently measure up to OEM parts in high quality is the extensive screening and certification processes that numerous aftermarket manufacturers stick to. These business recognize the relevance of creating top quality parts that can carry out dependably in numerous machinery and equipment. Therefore, consumers can now confidently pick this content aftermarket components recognizing that they supply equivalent quality to OEM parts at a Extra resources more budget friendly cost factor.

Modification Options for Particular Needs

For machinery maintenance, aftermarket parts supply a range of personalization choices customized to specific requirements, enabling companies to maximize their equipment performance effectively. Modification is an essential advantage of aftermarket components as it makes it possible for companies to adapt parts to fulfill unique demands that might not be dealt with by common OEM components.

Moreover, aftermarket parts providers can function closely with companies to understand their particular difficulties and style parts that address these concerns properly. Bobcat Aftermarket Parts. This customized technique to personalization can lead to better equipment functionality, increased performance, and lowered downtime because of tailored services that line up with the business's operational goals. By leveraging aftermarket get rid of personalization choices, services can maximize their machinery to carry out at its finest, inevitably leading to enhanced total operational effectiveness and cost-effectiveness

Swift Distribution and Lowered Downtime

Provided the customized services supplied by aftermarket parts for certain equipment demands, businesses can gain from speedy distribution and minimized downtime with efficient supply chain administration methods. Time is of the significance in the commercial market, where any equipment downtime can result in substantial economic losses. Aftermarket components vendors recognize this seriousness and usually stand out in offering fast distribution choices to minimize equipment idle time. By partnering with trusted aftermarket components providers, companies can access a variety of products quickly, guaranteeing that maintenance and fixings are accomplished promptly to obtain equipment back up and running.

Reduced downtime is vital for keeping efficiency degrees and conference project deadlines. By having accessibility to a diverse stock of aftermarket parts that can be delivered without delay, companies can prevent extensive durations of equipment inactivity. This performance in supply chain management not only saves time yet likewise adds to set you back financial savings by decreasing the impact of downtime on total procedures. To conclude, the swift distribution of aftermarket components plays an essential function in decreasing downtime, improving functional effectiveness, and eventually ensuring the seamless performance of equipment and hefty tools.

Final Thought

Unlike OEM (Original Devices Producer) components that may be restricted to visite site specific dealerships or makers, aftermarket parts are widely generated by numerous third-party manufacturers (Bobcat Aftermarket Parts). Additionally, the affordable market for aftermarket components frequently results in reduced costs and promotions, allowing consumers to obtain high quality components at a decreased price contrasted to OEM parts

With innovations in making procedures and top quality control requirements, aftermarket parts now use a degree of quality that is comparable to OEM components. In the past, there was a typical misunderstanding that aftermarket components were of inferior high quality contrasted to initial tools manufacturer (OEM) parts.One of the main reasons aftermarket components currently equal OEM components in high quality is the rigorous screening and qualification procedures that lots of aftermarket makers adhere to.